Noble Metal Heat Exchangers

| Contents: Noble Metals Titanium **Niobium** Click here to find out about special pricing for the steel pickling industry! Nickel Alloys Tantalum Zirconium Return to Heat Exchangers Noble Metals The Rasmussen Company specializes in custom corrosion resistant process equipment, including heat exchangers, from titanium, nickel alloys, tantalum, niobium, or zirconium.

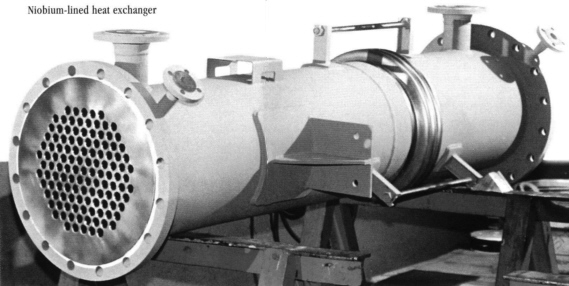

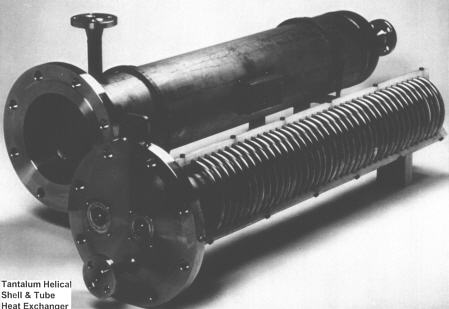

See the Raw Materials section for extensive data on different grades, mechanical properties, and corrosion data on titanium. Titanium heat exchangers are typically used in, but not limited to, applications involving chlorides and hydroxides used in bleaching processes in the paper industry, oxidative environments, nitric acids, and chromic acids. Titanium is also virtually inert to the effects of salt water. Contact the Rasmussen Company with your inquiry for custom equipment made from titanium.  The Rasmussen Company specializes heat exchangers made from niobium. These include shell and tube type heat exchangers, but others types, such as immersion heating coils, are available. In fact, niobium shell and tube heat exchangers are currently approximately half the cost of the graphite heat exchangers commonly used in the steel industry for pickling applications (as of August 20, 2002). Contact the Rasmussen Company to find out more about pricing for heat exchangers used in pickling applications. Niobium is extremely corrosion resistant in a wide variety of demanding environments. Its advantages include exceptional durability, excellent heat transfer properties, years of performance without lost production, and eliminating the added expense of back-up equipment.  The principal mode of failure of niobium (as is the same with tantalum) is by hydrogen embrittlement. If niobium is exposed to higher temperatures, where corrosion rates are unacceptable, hydrogen embrittlement will accompany the corrosion. If niobium is polarized cathodically, by galvanic coupling to a more active metal such as iron, aluminum or nickel, or by chemical attack, the niobium will absorb hydrogen even at room temperature. Niobium reacts with almost all salt solutions and acids producing a thin amorphous oxide film. Therefore, even though bare niobium would be at the active or anodic end of the electromotive series (similar to aluminum or iron), the presence of the passive oxide film increases the potential and elevates niobium to the more noble end of the electromotive series. As a result, when niobium is connected to another metal such as aluminum or steel to form a galvanic couple, niobium becomes cathodic. The more active metal, aluminum or steel, will dissolve; the cathodic reaction produces hydrogen, which will embrittle the niobium. Therefore, it is essential that niobium and its alloys are maintained anodic when connected to another metal. Niobium and Nb1Zr possess outstanding resistance to liquid metal corrosion. In addition to its excellent resistance to corrosion by molten alkali metals, niobium is also highly resistant to attack by sodium vapor at high temperatures and pressures. Alloy Nb1Zr (contains 1% zirconium) improves liquid metal corrosion resistance. Zirconium reacts with the oxygen associated with the liquid metal to form ZrO2 precipitates. This prevents oxygen from reacting with the niobium and forming a solid solution and surface layer of NaNbO2, which can cause embrittlement. Common fabrication techniques can lower the corrosion resistance of weld areas in many metals. Weld deposit or fusion zone segregation is an unavoidable problem in the cast microstructure of the weld, causing corrosion attack of the weld and / or precipitation of brittle intermetallics. Pure niobium has no segregation in the cast structure of the weld deposit, making it more corrosion resistant than alternative alloyed materials. Contact the Rasmussen Company to find out more about niobium. Nickel Alloy Heat Exchangers Nickel alloys exhibit exceptional corrosion resistance and strength in a wide variety of applications. See the Raw Materials section for extensive data on different grades and mechanical properties for nickel alloys. Nickel alloys are suitable for a wide variety of applications due to the many different compositions and properties associated with the different alloys. The Rasmussen Company specializes in shell and tube type heat exchangers, though other types are available. Contact the Rasmussen Company with your inquiry for custom equipment made from a nickel alloy.  The Rasmussen Company also specializes in custom heat exchangers made from tantalum. The most common are shell and tube type heat exchangers, but others types, such as immersion heating coils, are available. Tantalum is extremely corrosion resistant in a wide variety of demanding environments including nearly all organic and inorganic compounds in the pharmaceutical and chemical process industries. In fact, it is even more corrosion resistant than niobium. Its advantages include: · Superior corrosion resistance. Inert in almost all environments up to temperatures of 450°F · Naturally occurring oxide film on tantalum's surface makes it resistant to corrosion in even the most severe acid environments and completely resistant to organic compounds. · Assured end-product purity due to absence corrosion, scaling and flaking · Faster validated cleanout between batches · Maintenance free operation · Long service life · Excellent strength and durability, strength, and workability  Due to their much longer service life and maintenance free operation, tantalum heat exchangers are more cost-effective than equipment made from nickel-based alloys, impregnated graphite, or other materials. Because of its strength and workability, tantalum can be used in thin walled tubing for multipurpose helical coils, shell and tube heat exchangers, and bayonet heaters. This yields higher thermal efficiency, requiring less heat transfer surface. Thin sheets of tantalum can be clad in heating coils and tubesheet facings for the most cost-effective use of the metal.  The Rasmussen Company also supplies tantalum equipment for the pharmaceutical and chemical industries. We have assisted in the development of these major design benefits:

Tantalum is one of the most corrosion resistant materials available. While its resistance to acid is comparable to that of glass and platinum, it is far less susceptible to breakage than glass and much less expensive than platinum. Tantalum is inert to practically all organic and inorganic compounds at temperatures under 300°F. Tantalum is essentially acid-proof, except for hydrofluoric and fuming sulfuric acids. At temperatures under 300°F, it is inert to all concentrations of hydrochloric acid and nitric acid (including fuming), 98% sulfuric acid, 85% phosphoric acid, and to aqua regia. Tantalum is also completely inert to body fluids. In addition, it is fairly resistant to dilute alkaline solutions. Tantalum's resistance to oxidation by various gases is also very good at low temperatures. Tantalum-tungsten alloys containing more than 18% tungsten are inert to 20% hydrofluoric acid at room temperature. These alloys are also somewhat more oxidation resistant than pure tantalum. They also appear to have the same corrosion resistance as pure tantalum. Contact the Rasmussen Company to find out more about Tantalum. Zirconium Heat Exchangers The Rasmussen Company specializes in custom heat exchangers made from zirconium. They most commonly fabricate shell and tube type heat exchangers, but others types are available. Zirconium exhibits great resistance to high-temperature water and steam. Zirconium also exhibits excellent resistance to most organic and mineral acids as well as alkaline solutions and alkalis. It is particularly useful in contact with sulfuric and hydrochloric acids. Zirconium equipment is suitable for processes that cycle between acidic and basic conditions, being corrosion resistant over a broad range of pH's. It is also excellent when used in service with reducing environments. It is also immune to crevice corrosion in chloride solutions. Contact the Rasmussen Company to find out more about Zirconium.  |

|

Please contact us with any inquiry! Rasmussen Company, Inc. Phone: 800-558-0575 (in the U.S.) or 262-695-3320 |